Page 61 - Kỷ yếu hội thảo quốc tế: Ứng dụng công nghệ mới trong công trình xanh - lần thứ 9 (ATiGB 2024)

P. 61

52 TRƯỜNG ĐẠI HỌC SƯ PHẠM KỸ THUẬT - ĐẠI HỌC ĐÀ NẴNG

colleagues [24] proposed using the Avrami-Erofeev In this context, Mg represents magnesium, while H 2

equation to approximate the kinetics of these reactions: refers to hydrogen, with (s) and (g) denoting the solid

n and gas phases, respectively. The exothermic reaction

X=1-e -(Kt) (3) that occurs during the formation of magnesium hydride

We have X as the reactant, The rate constant, (MgH2) through hydrogen absorption results in the

denoted as K, depends on time (t) and can be release of heat (Q). Conversely, the endothermic

represented by an integer or half-integer (n), depending decomposition of magnesium hydride to release

on the specific reaction mechanism: hydrogen requires a similar amount of heat input.

C -C Among the substances explored for hydrogen

X= H 1 (4) storage, magnesium hydride (MgH2) has emerged as a

C -C promising choice for hydrogen storage owing to its

2 1

substantial storage capacity (7.6% by weight),

The reactant concentration is defined by CH, which favorable reversibility of hydrogen uptake and release

is the actual hydrogen concentration, and C1, the initial processes, and abundant magnesium resources on Earth,

hydrogen concentration, and C2 is the final hydrogen MgH2 has attracted significant interest [26-28].

concentration.

However, the implementation of MgH2 in onboard

The rate constant can be expressed as: hydrogen storage systems is still limited due to high

-E a operating temperatures and slow reaction rates. This is

K= K P RT (5) attributed to the strong bond energy between

( ) .e

magnesium and hydrogen atoms (ΔH = 76 kJ/mol) and

The rate constant K(P) is influenced by the the relatively high activation energy barrier of the

deviation of the actual hydrogen pressure from the reaction (Ea = 160 kJ/mol) [29-31]. To address these

equilibrium pressure, with Ea representing the limitations, researchers have focused on enhancing the

activation energy. thermodynamic and kinetic characteristics of MgH2

through methods such as alloying, nanostructuring, and

The mass transfer rate K(P) and the reaction rate

during hydrogen compression using metal hydrides using catalysts [32-34].

(MH) are strongly influenced by both kinetic 3.2. TiFe

parameters and the pressure-concentration-temperature The TiFe alloy has a relatively narrow

(PCT) characteristics are critical in understanding the homogeneity range, primarily concentrated between

hydrogen-metal system. Heat, mass transfer models in 49.7% and 52.5% Ti at 1085°C [36, 37].

MH reactors have leveraged this approach to simulate

hydrogen compression processes. Observing Figure 3, we see that the neighboring

3. PRELIMINARY ASSESSMENT OF phases of TiFe include TiFe₂ (in the Fe-rich region) and

VARIOUS METAL HYDRIDE β-Ti (which can dissolve up to 21% Fe in the Ti-rich

REPRESENTATIVES FOR HYDROGEN region). The hydrogen absorption properties of this

STORAGE alloy are strongly influenced by its chemical makeup

and the existence of secondary phases. Due to the

3.1. MgH2 narrow composition range of the TiFe phase,

chemically balanced TiFe alloys, either Fe-rich

(TiFe₁.₀₁₂) or Ti-rich (TiFe₀.₉₀₅), will exhibit different

properties. In particular, alloys with high Ti content,

due to the creation of β-Ti precipitates, possess the

capability to absorb hydrogen at ambient temperature

without requiring initial activation. The enthalpy of

formation of TiFe, measured at 1167°C, is ΔH = −31.0

kJ.mol⁻¹ [39].

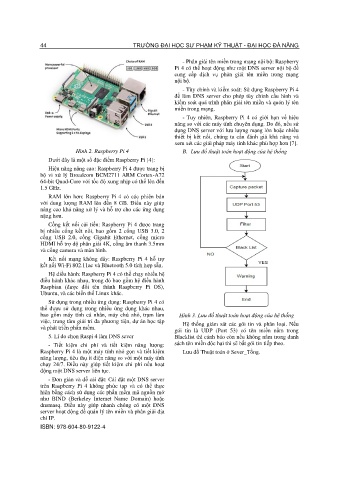

Figure 2. Diagram of hydrogen

absorption and release in the MgH 2 compound

The absorption and desorption process (as depicted

in Figure 2) can be represented by the following

reaction:

Mg(s)+H (g) MH (s)+Q (6)

2 2

ISBN: 978-604-80-9779-0