Page 69 - Kỷ yếu hội thảo quốc tế: Ứng dụng công nghệ mới trong công trình xanh - lần thứ 9 (ATiGB 2024)

P. 69

60 TRƯỜNG ĐẠI HỌC SƯ PHẠM KỸ THUẬT - ĐẠI HỌC ĐÀ NẴNG

Ne = m . Ni = Pe . Vh. i . n = 0,838 . 0,163. 1 . 3600 = 4,1

(kW) 30τ 30 . 4

Effective power (Ne) of the Honda GX160 engine

after improvement:

Ne = m . Ni = Pe . Vh. i . n = 0,8696. 0,183. 1 . 3600 = 4.77

(kW) 30τ 30 . 4

Torque Me of the Honda GX160 Engine:

Ne

Ne

Me = = Ne . 60 ≈ 9,55 (N. m)

ω 2πn n

Where Ne (W) is the effective power, and n (rpm) is

the engine speed.

Me = 9,55 Ne = 9,55 4,1 = 0,01087 (N.m)

n 3600

Torque Me of the Honda GX160 engine after

improvement:

Me = 9,55 Ne = 9,55 4,77 = 0,0126( N.m)

n 3600

There are various ways to increase the compression

ratio of the GX160 engine to suit NH3 fuel, such as

modifying the cylinder head, increasing bore diameter

D, increasing piston stroke, using thinner gaskets, or

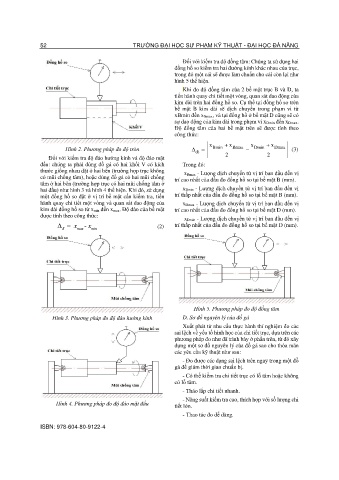

changing the piston shape. In this study, the chosen Figure 2. Piston-Connecting Rod-Crankshaft of the

solution is to increase the piston diameter to raise the Honda GX160 Engine after Modification

engine's compression ratio, without significantly

altering or intervening in the structure of other Based on Figure 1, increasing the compression ratio

components and systems of the engine. To select and leads to a significant rise in engine power. However, in

determine the piston specifications that meet the engine design, the compression ratio is a crucial factor

operating conditions and engine specifications, the for gasoline engines as it directly influences

research team designed a new piston based on the old performance and operation. However, a compression

piston's structure and dimensions, ensuring it is strong ratio that is too high can cause serious issues, such as

enough and does not negatively impact other damage to the piston, cylinder, and gaskets, leading to

components. a reduced engine lifespan. Therefore, to maintain the

compression ratio within the range of ɛ = 10 ÷ 15 while

By keeping other parameters constant and only ensuring engine safety, the case where D=72mm was

changing the piston diameter D, the variations in chosen. The structure and technical specifications of

indicated power Ni , effective power N e , and the Honda GX160 engine after the modification are

compression ratio are illustrated in the graph: shown in Figure 2.

2.3. Power, Pressure, and Reaction Forces

After adjusting the piston diameter to increase the

compression ratio to 10, the modified Honda GX160

engine's indicated power (Ni) increased to 5.545 kW,

up from the initial 4.631 kW. The brake power (Ne) also

rose to 4.77 kW from the original 4.1 kW. Additionally,

the torque (Me) at the crankshaft output saw a

significant increase to 0.0126 N.m, compared to the

initial 0.01087 N.m. These improvements not only

enhanced engine performance but also increased the

engine's load-bearing capacity and efficiency. Notably,

when using NH3 as fuel, the engine demonstrated a

Figure 1. Graph of Ni , Ne , and Compression much better combustion efficiency than before,

Ratio with Varying Piston Diameter contributing to economic efficiency and reducing

environmental impact.

ISBN: 978-604-80-9779-0