Page 70 - Kỷ yếu hội thảo quốc tế: Ứng dụng công nghệ mới trong công trình xanh - lần thứ 9 (ATiGB 2024)

P. 70

th

HỘI THẢO QUỐC TẾ ATiGB LẦN THỨ CHÍN - The 9 ATiGB 2024 61

Table 3. Input Parameters of the Figure 4 shows the P-α graph of the engine.

Engine After Modification Analysis of the P-α graph reveals a significant

improvement in the peak pressure within the

No. Parameter Value Unit Symbol

combustion chamber after modification. Specifically,

1 Effective power 4,77 kW N e at a crank angle of 372 degrees, the maximum pressure

2 Compression Ratio 10 V (Pmax) before modification was 4.801 MPa, whereas the

3

3 Cylinder Volume 183 cm V h modified version achieved 5.7284 MPa. This indicates

Adiabatic Expansion Index of a more efficient combustion process, with a more

4 1,45 m complete burn of the ammonia-air mixture, resulting in

Residual Gas

5 Heat Utilization Coefficient at z 0,85 x z higher pressure in the combustion chamber.

6 Heat Utilization Coefficient at b 0,89 x b 2.4. Piston-Connecting Rod-Crankshaft Durability

Testing

7 Pressure Increase Coefficient 3,45 l

After completing the piston design, the durability

8 Additional Charge Coefficient 1,07 l 1

testing process is crucial to ensure the product meets

9 Scavenging Coefficient 1 l 2 performance and safety requirements. SolidWorks

software was used to simulate stress, displacement,

Correction Coefficient for Specific safety factor, and temperature of the piston under

10 1,1 l t

Heat

various operating conditions.

11 Graph Filling Coefficient 1 j đ

In the calculation and analysis process, the authors

The engine modifications resulted in significant determined the maximum pressure to be pz=6,873 MPa.

improvements, such as increased combustion chamber This is the maximum pressure exerted by the gas on the

pressure, gas force, torque, and engine power. At the pz.π.

2

same time, the stability of the inertia forces post- piston top. Using the formula F= 4 , the resulting

modification helped reduce vibrations, wear, and force was F=27.983,44754 N. This force represents the

extended the lifespan of the piston, crankshaft, and maximum load the mechanism must withstand during

connecting rod. The modifications not only enhanced maximum power operation.

performance but also ensured stability and durability

during operation, as illustrated in Figure 3.

Figure 5. Structural Mesh

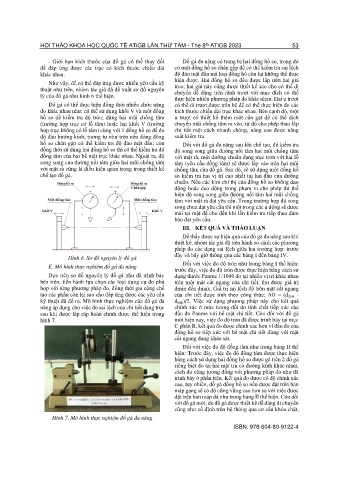

Figure 3. Graphs of Pkt, Pj, P

Figure 6. Simulation and Durability Testing of the

Piston, Crankshaft, and Connecting Rod

a) Stress; b) Displacement;

Figure 4.Graph of P-anpha c) Strain Index; d) Safety Factor.

ISBN: 978-604-80-9779-0